Fiberglass HT52H is a special kind of material that many people and industries are starting to use more and more. Fiberglass HT52H is known for being very strong, yet lightweight, which makes it perfect for building things that need to last a long time without breaking easily. People often use fiberglass HT52H in construction, boats, cars, and even in electrical parts because it does not rust or get damaged by water. One of the best things about fiberglass HT52H is that it is safe to handle and easy to shape into different designs, which is why engineers and designers love it. Unlike other materials like metal or wood, fiberglass HT52H can stay strong even in harsh weather, making it reliable for many outdoor projects. It is also a cost-effective solution for people who want long-lasting materials without spending too much money.

Fiberglass HT52H is not only strong and durable, but it is also very versatile, which is why it is becoming popular worldwide. Many people do not realize that fiberglass HT52H can also resist high temperatures and chemicals, which makes it perfect for special projects in factories or labs. This material is also lighter than metal, which makes it easier to carry and install in different places. Builders and DIY enthusiasts can use fiberglass HT52H for fences, panels, roofs, and many decorative items because it is easy to cut and mold into the shapes they want. Even in marine projects like boat hulls, fiberglass HT52H performs very well because it does not absorb water and stays strong even in salty environments.

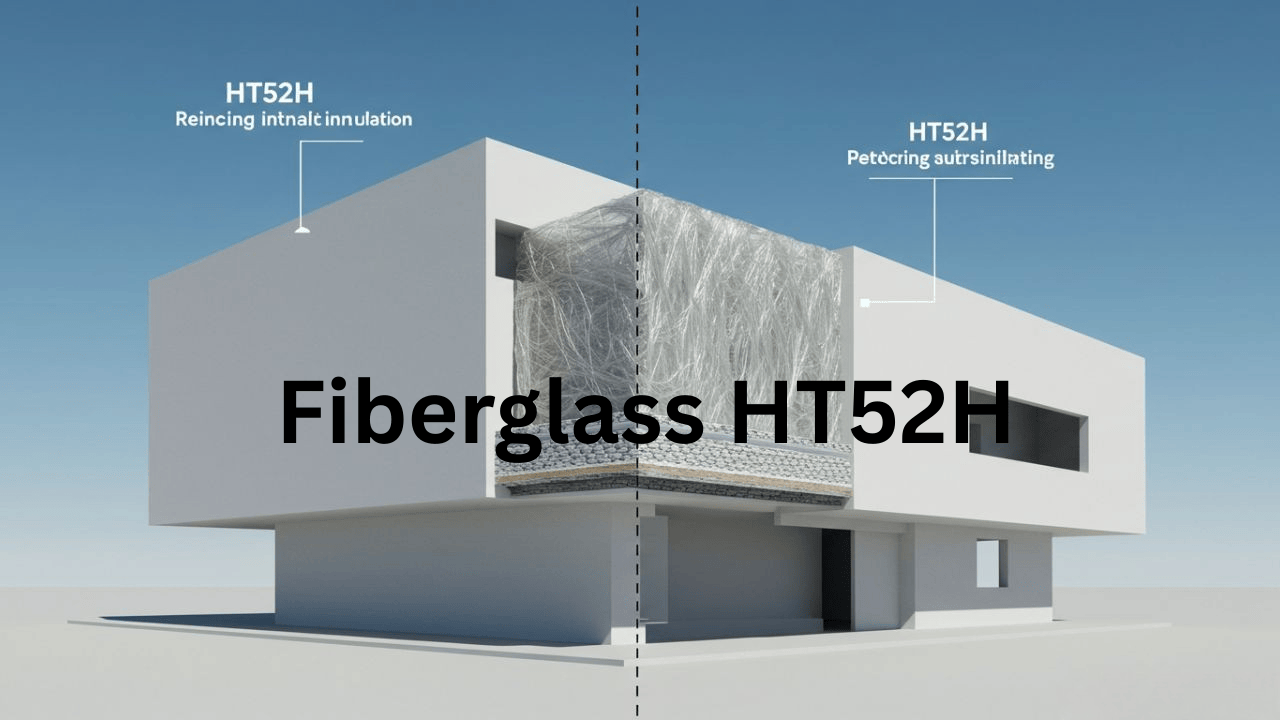

What is Fiberglass HT52H and Why It’s Special

Fiberglass HT52H is a strong and lightweight material that is widely used in construction, manufacturing, and DIY projects. It is made by combining glass fibers with special resin to create a product that is both tough and flexible. What makes fiberglass HT52H special is its ability to resist water, rust, and heat, which allows it to last much longer than ordinary materials like wood or metal. People use it in industries like automotive, marine, and electronics because it can handle stress without breaking. Its lightweight nature makes it easy to transport and install, while its durability saves money over time. Fiberglass HT52H is also easy to mold into various shapes, making it perfect for both functional and decorative purposes in many different projects.

Fiberglass HT52H Properties: Strength, Heat Resistance, and Durability

Fiberglass HT52H is known for its amazing combination of strength, heat resistance, and durability. Its glass fiber structure makes it strong enough to handle heavy loads without bending or breaking. Unlike wood or metal, it does not warp, rust, or corrode over time, which makes it ideal for outdoor use. Fiberglass HT52H also performs well under high temperatures, making it suitable for industrial applications that involve heat. Its durability ensures that it can last for many years without needing replacement or frequent repairs. Additionally, fiberglass HT52H is resistant to chemicals and moisture, so it stays reliable even in harsh environments. These properties make it one of the most trusted materials for both everyday projects and large-scale industrial work.

Common Uses of Fiberglass HT52H in Daily Life and Industry

Fiberglass HT52H is used in many areas of daily life and industry because of its strength and flexibility. In construction, it is often used for panels, roofs, and fencing because it can withstand harsh weather. In the automotive industry, fiberglass HT52H is used for car body parts, dashboards, and protective panels. Boat manufacturers rely on it for hulls and decks because it does not absorb water and stays strong in salty environments. DIY enthusiasts also use fiberglass HT52H for home improvement projects, like shelves, decorations, and storage boxes. Even electronics manufacturers use it for insulators and protective casings. Its versatility, lightweight nature, and durability make fiberglass HT52H a reliable material in both small and large-scale projects across different industries worldwide.

Fiberglass HT52H vs Other Materials: Why It Stands Out

When compared to other materials like wood, metal, or plastic, fiberglass HT52H stands out in many ways. Unlike metal, it does not rust or corrode when exposed to moisture, making it perfect for outdoor projects. Compared to wood, it does not warp, crack, or get damaged by insects, so it lasts longer. Unlike plastics, it can withstand higher temperatures and stress without breaking. Fiberglass HT52H is also lighter than metal, which makes it easier to carry and install. Its ability to resist chemicals, heat, and water gives it an edge over traditional materials. This combination of lightweight strength, durability, and versatility makes fiberglass HT52H one of the best choices for builders, engineers, and DIY enthusiasts alike.

How to Handle and Work with Fiberglass HT52H Safely

Working with fiberglass HT52H is safe if you follow simple precautions. Always wear gloves, a mask, and safety glasses when cutting or sanding the material to avoid irritation from fibers. Use proper tools, like fine-tooth saws or utility knives, to get clean cuts without damaging the material. Avoid inhaling dust by working in a well-ventilated area or using a dust extractor. Fiberglass HT52H can be molded with heat or special resins, but it is important not to overheat it, as extreme temperatures may cause damage. Clean tools and surfaces after work to prevent leftover fibers from causing skin irritation. Following these safety steps ensures that working with fiberglass HT52H is easy, effective, and risk-free for all users.

Advantages of Fiberglass HT52H for Builders and DIY Enthusiasts

Fiberglass HT52H offers many advantages for both professional builders and DIY enthusiasts. Its lightweight nature makes it easy to handle and transport, saving time and energy. Its strong and durable structure ensures that projects last longer with minimal maintenance. Builders appreciate its resistance to water, heat, and chemicals, which allows it to perform well in challenging environments. DIY enthusiasts like it because it is easy to cut, shape, and customize for different projects. It can be used for construction, decorations, furniture, and more. Using fiberglass HT52H also reduces overall costs because it is long-lasting and low-maintenance. These advantages make it an ideal material for anyone looking to combine strength, flexibility, and affordability in their projects.

Fiberglass HT52H in Construction: Tips for Long-Lasting Projects

Using fiberglass HT52H in construction requires some planning to ensure projects last long and perform well. It is important to choose the right thickness and type of fiberglass HT52H based on the project’s load and weather conditions. Always handle it carefully to avoid cracks or scratches during installation. Use compatible adhesives, resins, or fasteners to secure panels or components properly. Regular inspections help identify small damages early, preventing bigger problems later. Fiberglass HT52H can be painted or coated to add extra protection and enhance its appearance. By following these tips, construction projects using fiberglass HT52H will remain strong, durable, and visually appealing for years, making it a smart investment for builders.

Fiberglass HT52H in Marine and Outdoor Applications

Fiberglass HT52H is perfect for marine and outdoor projects because it resists water, salt, and harsh weather conditions. Boat manufacturers use it for hulls, decks, and other parts because it does not absorb water and stays strong in salty environments. Outdoor furniture, fencing, and panels made from fiberglass HT52H also last longer than wood or metal. Its resistance to heat, UV rays, and corrosion makes it ideal for rooftops, terraces, and playground equipment. Fiberglass HT52H is lightweight, which makes it easy to transport and install even in hard-to-reach places. These properties make it a reliable choice for projects that require both durability and low maintenance, ensuring safety and longevity in outdoor and marine environments.

Maintenance and Care Tips for Fiberglass HT52H

Fiberglass HT52H is low-maintenance, but some care can make it last even longer. Clean it regularly with mild soap and water to remove dirt, salt, and dust. Avoid harsh chemicals or abrasive tools that may scratch or damage the surface. Check for small cracks or chips and repair them promptly using resin or adhesives designed for fiberglass. Protect outdoor installations from extreme sunlight by applying UV-resistant coatings. For marine applications, rinse with fresh water after exposure to saltwater to prevent buildup. Proper storage, like keeping unused sheets in a dry, cool place, also helps maintain quality. With simple care, fiberglass HT52H can stay strong, look great, and continue performing well for many years.

Conclusion

Fiberglass HT52H is a very strong and useful material that can be used in many places like homes, boats, cars, and buildings. It does not get damaged easily by water, heat, or chemicals, which makes it last a long time. People like using it because it is light, easy to shape, and safe to handle. Using fiberglass HT52H can make your projects stronger and more reliable without spending too much money.

It is also a material that can help both beginners and experts do creative projects. From construction to outdoor furniture, fiberglass HT52H works well everywhere. With proper care, it can stay in great condition for years. If you want a material that is strong, safe, and easy to use, fiberglass HT52H is a smart choice for any project.

FAQs

Q: What is fiberglass HT52H used for?

A: It is used in construction, boats, cars, furniture, and electronics because it is strong, light, and water-resistant.

Q: Is fiberglass HT52H safe to handle?

A: Yes, it is safe, but wearing gloves and a mask while cutting or sanding helps prevent irritation.

Q: How do I take care of fiberglass HT52H?

A: Clean it with mild soap and water, check for cracks, and use UV or protective coatings for outdoor projects.